Product parameters:

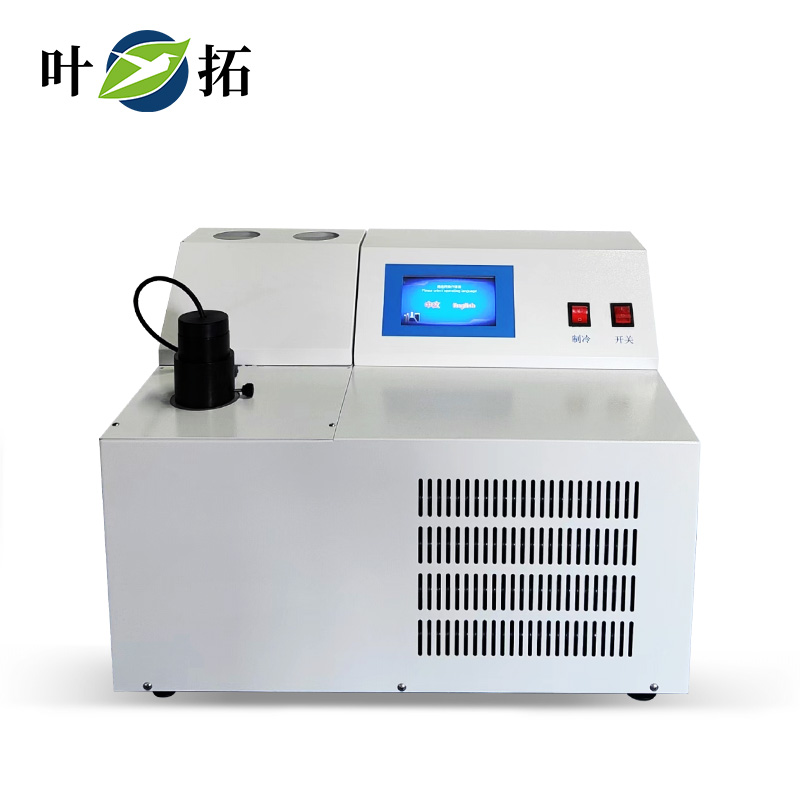

Equipment model: YT-900Z (alcohol bath)

Measurement range: Room temperature~-75 ℃

Temperature control accuracy: ± 0.1 ° C

Resolution:/

Number of experimental holes:/

Relative humidity: ≤ 80%

Cooling rate: not less than 70 ° C/h

Refrigeration method: Compressor refrigeration

Applicable environment: Temperature ≤ 40 ℃; Humidity ≤ 80%

Testing method: Infrared photoelectric detection

Temperature sensor: imported PT100 sensor

Power: 1500W

Power supply voltage: AC220V 50Hz

External dimensions:/

Instrument weight: approximately 36kg

Printing: Thermal printing

Storage data: 2000 entries

- Product Details

- Product manual

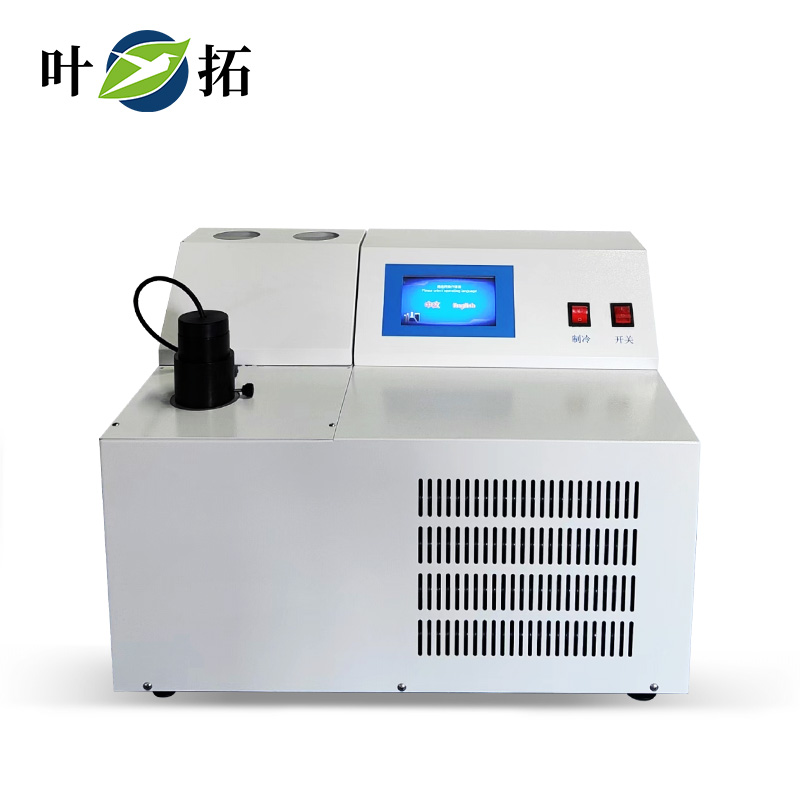

Yetuo YT-900Z (alcohol bath) metal bath

Model: YT-900Z (Alcohol Bath)

Product Overview:

This instrument is used to determine the pour point and pour point of transformer oil, lubricating oil, and light oil (not applicable to petroleum products with high viscosity). The instrument adopts a color touch LCD screen display, a Chinese human-machine dialogue interface, easy to operate, intuitive, and has the function of error operation software prompt modification. The interface is clear and can print test data, achieving automation of the test process. It is an ideal product for measuring pour point and pour point

This instrument complies with the national standards GB510 "Determination of Condensation Point of Petroleum Products" and GB3535 "Determination of Petroleum Pour Point", as well as GB/T6986-1986 Petroleum Cloud Point Determination Method. It is suitable for determining the condensation point/pour point of light oils in refineries, power plants, railways, shipping, oil companies, and oil commercial sectors

Yetuo YT-900Z (Alcohol Bath) Metal Bath Product Features

Chinese LCD touch screen display, controlled by microprocessor, dynamic graphic simulation of working status

Design dual hole condensation point test, accurate and easy to use

● Automatic detection of the entire test process, automatic tilt detection at 45 degrees, alarm prompt for 1 minute tilt, automatic alarm upon completion of the test, and printing of the results

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore